06 Dec Plastics

Pellets

The color of plastic pellets is often measured before the pellets are extruded, or molded, into a final product. Plastic pellets are typically translucent and non-uniform in size. Therefore, special accessories and presentation techniques are required to provide repeatable results.

Hunterlab Solutions

Many HunterLab spectrophotometers have the versatility to accommodate most applications of color measurement. However, based on 60+ years of experience and a thorough understanding of our customers’ needs and product use, these particular instruments are most suited for this industry application.

NEW Aeros Smart noncontact spectrophotometer provides the unique ability to easily and accurately measure inconsistent, heavily textured, non-uniform samples.

40% of our customers prefer this instrument because of its compact design and integrated display, so does not require a PC and external software.

10% of HunterLab customers select this instrument for its large 44 mm (1.75 inches) measuring port, and for its level of sophistication, simplicity, and versatility.

10% of our customers select the hand-held MiniScan EZ because it is rugged, lightweight and ergonomically designed and travels anywhere, from the lab to the production line, indoors or outdoors

HunterLab’s next generation SpectraTrend HT spectrophotometer takes color quality control to its highest level with 0/30 design for ultimate precision.

If you are unsure which instrument type is right for your samples, please call or email us for technical support and we will be happy to assist you in making the proper instrument selection.

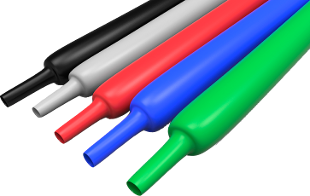

Extruded Plastic

Plastics production demands tight tolerances and efficient use of materials. Maintaining a high level of color quality control is a challenge that can often lead to material waste, line shutdown, extensive operator involvement, and product scrap and rework. HunterLab understands these challenges, and provides a complete line of products for laboratory and on-line color monitoring and control designed to improve efficiencies and reduce waste.

Hunterlab Solutions

Many HunterLab spectrophotometers have the versatility to accommodate most applications of color measurement. However, based on 60+ years of experience and a thorough understanding of our customers’ needs and product use, these particular instruments are most suited for this industry application.

40% of our customers prefer this instrument because of its compact design and integrated display, so does not require a PC and external software.

10% of HunterLab customers select this instrument for its large 44 mm (1.75 inches) measuring port, and for its level of sophistication, simplicity, and versatility.

10% of our customers select the hand-held MiniScan EZ because it is rugged, lightweight and ergonomically designed and travels anywhere, from the lab to the production line, indoors or outdoors

HunterLab’s next generation SpectraTrend HT spectrophotometer takes color quality control to its highest level with 0/30 design for ultimate precision.

If you are unsure which instrument type is right for your samples, please call or email us for technical support and we will be happy to assist you in making the proper instrument selection.

Bottles

Plastic bottles are diverse in size, shape, and color. As is common to all plastic products, bottles can be opaque, translucent or transparent. The requirements for color measurement can extend past transmitted or reflected spectral data to also include CIE L*a*b* Color, Yellowness, Haze, and other appearance-related attributes. Plastic sample type will dictate the proper measurement instrument and technique according to the HunterLab guidelines set forth below.

Opaque Bottles are impenetrable by light, and are best measured using a Directional 45°/0° reflectance instrument, or Diffuse d/8° Sphere reflectance instrument:

– If you are measuring opaque bottles and desire to quantify a numeric value to visual perception, then the proper measurement technique is to employ a reflectance spectrophotometer that uses Directional 45/0° reflectance geometry. This is the geometry that most closely matches how the human eye sees color.

– If you are measuring opaque bottles and desire to negate the gloss and texture component of the sample and look at color only, then the proper technique is to employ a Diffuse d/8° reflectance instrument.

Translucent Bottles allow light to pass through, but only diffusely, so that objects on the other side cannot be clearly distinguished. Both reflective and transmittance measurement modes may work well depending on the translucency of the sample. As a rule of thumb,

– If at the path length that your customer will view the sample, you can see slight details of your thumb or finger through the plastic, then transmittance is the preferred measurement method.

– If you cannot see slight details, then reflectance is preferred.

Path length is defined as the thickness of the sample from where the light enters to where it exits the sample.

Transparent Bottles allow light to pass through with little or no interruption or distortion so that objects on the other side can be clearly seen. These bottles can only be measured using transmission instrumentation.

Additionally, certain metrics and indices such as CIE L*a*b* Color, Whiteness, Yellowness and Haze require the use of specific geometries and specific measurement modes. For the proper instrument selection for your application please refer to the following chart: HunterLab Solutions Chart.

Hunterlab Solutions

Many HunterLab spectrophotometers have the versatility to accommodate most applications of color measurement. However, based on 60+ years of experience and a thorough understanding of our customers’ needs and product use, these particular instruments are most suited for this industry application.

10% of our customers select the hand-held MiniScan EZ because it is rugged, lightweight and ergonomically designed and travels anywhere, from the lab to the production line, indoors or outdoors

10% of our customers select the hand-held MiniScan EZ because it is rugged, lightweight and ergonomically designed and travels anywhere, from the lab to the production line, indoors or outdoors.

30% of our customers select this instrument for its extended wavelength measurement and its ability to measure both reflected and transmitted color of samples that are transparent to opaque.

If you are unsure which instrument type is right for your samples, please call or email us for technical support and we will be happy to assist you in making the proper instrument selection.

Preforms

Preforms come in a multitude of sizes, shapes and colors. They can range from opaque to translucent or transparent, so require different measurement techniques depending on the sample type.

Opaque Preforms are impenetrable by light and are best measured using a Diffuse d/8 Sphere reflectance instrument.

Translucent Preforms allow light to pass through, but only diffusely, so that objects on the other side cannot be clearly distinguished. Both reflective and transmittance measurement modes may work well depending on the translucency of the sample. As a rule of thumb,

– If at the path length that your customer will view the sample, you can see slight details of your thumb or finger through the preform, then transmittance is the preferred measurement method.

– If you cannot see slight details, then reflectance is preferred.

Path length is defined as the thickness of the sample from where the light enters to where it exits the sample.

Transparent Preforms allow light to pass through with little or no interruption or distortion so that objects on the other side can be clearly seen. These preforms can only be measured using transmission instrumentation.

Additionally, certain metrics and indices such as CIE L*a*b* Color, Yellowness, Whiteness, or Haze require the use of specific geometries and specific measurement modes. For the proper instrument selection for your application please refer to the following chart: HunterLab Solutions Chart.

Hunterlab Solutions

Many HunterLab spectrophotometers have the versatility to accommodate most applications of color measurement. However, based on 60+ years of experience and a thorough understanding of our customers’ needs and product use, these particular instruments are most suited for this industry application.

10% of our customers select the hand-held MiniScan EZ because it is rugged, lightweight and ergonomically designed and travels anywhere, from the lab to the production line, indoors or outdoors

NEW Vista spectrophotometer with the unique ability to capture both visible range transmission color and haze with a single measurement is a replacement for ColorQuest XT.

If you are unsure which instrument type is right for your samples, please call or email us for technical support and we will be happy to assist you in making the proper instrument selection.

Plaques

Lot-to-lot or piece-to-piece color consistency is an important indicator of quality for many plastic items. The process of pressing a plaque for the purpose of color measurement is commonplace in plastics processing, with well-established ASTM guidelines for best practices. Plastic plaques can range from opaque to translucent or transparent, so require different measurement techniques depending on the sample type.

Opaque Plaques are impenetrable by light and are best measured using a Directional 45°/0° reflectance instrument or a Diffuse d/8° reflectance instrument:

– If you are measuring opaque plaques and desire to quantify a numeric value to visual perception, then the proper measurement technique is to employ a directional 45/0° reflectance instrument. This is the geometry that most closely matches how the human eye sees color.

– If you are measuring opaque plaques and desire to negate the gloss and texture components of the sample and look at color only, then the proper technique is to employ a Diffuse d/8° reflectance instrument.

Translucent Plaques allow light to pass through, but only diffusely, so that objects on the other side cannot be clearly distinguished. Both reflective and transmittance measurement modes may work well depending on the translucency of the sample. As a rule of thumb,

– If at the path length that your customer will view the sample, you can see slight details of your thumb or finger through the plaque, then transmittance is the preferred measurement method.

– If you cannot see slight details, then reflectance is preferred.

– Path length is defined as the thickness of the sample from where the light enters to where it

Hunterlab Solutions

Many HunterLab spectrophotometers have the versatility to accommodate most applications of color measurement. However, based on 60+ years of experience and a thorough understanding of our customers’ needs and product use, these particular instruments are most suited for this industry application.

10% of our customers select the hand-held MiniScan EZ because it is rugged, lightweight and ergonomically designed and travels anywhere, from the lab to the production line, indoors or outdoors

10% of our customers select the hand-held MiniScan EZ because it is rugged, lightweight and ergonomically designed and travels anywhere, from the lab to the production line, indoors or outdoors

30% of our customers select this high-performance instrument for its extended wavelength measurement and its ability to measure both reflected and transmitted color.

30% of our customers select this instrument for its extended wavelength measurement and its ability to measure both reflected and transmitted color of samples that are transparent to opaque.

NEW Vista spectrophotometer with the unique ability to capture both visible range transmission color and haze with a single measurement is a replacement for ColorQuest XT.

If you are unsure which instrument type is right for your samples, please call or email us for technical support and we will be happy to assist you in making the proper instrument selection.

Ophthalmic Lenses

Plastic lenses are currently the most commonly prescribed lens, due to their relative safety, low cost, ease of production, and outstanding optical quality. Color measurement is performed throughout the manufacturing process of ophthalmic lenses and blanks, from incoming QA tests of the liquid polymer ingredients to that of their finished products, including the film used as polarizers in prescription sunglasses and anti-reflection coatings. Color measurement is also used for weathering or performance testing, and color testing for lot-to-lot tint characteristics.

Hunterlab Solutions

Many HunterLab spectrophotometers have the versatility to accommodate most applications of color measurement. However, based on 60+ years of experience and a thorough understanding of our customers’ needs and product use, these particular instruments are most suited for this industry application.

30% of our customers select this high-performance instrument for its extended wavelength measurement and its ability to measure both reflected and transmitted color.

30% of our customers select this instrument for its extended wavelength measurement and its ability to measure both reflected and transmitted color of samples that are transparent to opaque.

If you are unsure which instrument type is right for your samples, please call or email us for technical support and we will be happy to assist you in making the proper instrument selection.

Sorry, the comment form is closed at this time.