AN 1001.01 ALPHA

AN 1001.01 ALPHA

Measuring the Water Whiteness of Liquids Using the APHA Index.

AN 1002.01 Standard Observer

AN 1002.01 Standard Observer

CIE Standard Observers and calculation of CIE X, Y, Z color values.

AN 1005 HunterLab vs CIE Lab

AN 1005 HunterLab vs CIE Lab

Measuring Color using Hunter L, a, b vs CIE 1976 L*a*b*.

AN 1007.01 Geometric Attribute

AN 1007.01 Geometric Attribute

Measuring the Geometric Attribute of Your Products.

AN 1013 Averaging

AN 1013 Averaging

Averaging in Color Measurement.

AN 1018 Hitch Stdz

AN 1018 Hitch Stdz

Using Hitch Standardization on a Series of Color Measuring Instruments.

AN 1031 Identification of Measurement Parameters

AN 1031 Identification of Measurement Parameters

Identification of Measurement Parameters.

AN 1033 Color versus Appearance

AN 1033 Color versus Appearance

Understanding the difference between measuring color and measuring appearance.

HunterLab Solution Matrix

HunterLab Solution Matrix

Geometry, Measurement Modes, and Indices.

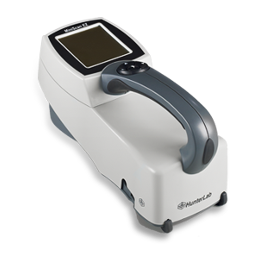

MM 5019 Measuring Flat Opaque Solids with ColorQuest XE

MM 5019 Measuring Flat Opaque Solids with ColorQuest XE

Measurement method for flat, opaque solids using the UltraScan PRO, UltraScan VIS, or ColorQuest XE.

MM 5001 Measuring Translucent and Opaque Bottles with ColorQuest XE

MM 5001 Measuring Translucent and Opaque Bottles with ColorQuest XE

Measurement method for translucent and opaque bottles using the UltraScan VIS, UltraScan PRO, and ColorQuest XE.

MM 5002 Measuring Transparent Bottles with ColorQuest XE

MM 5002 Measuring Transparent Bottles with ColorQuest XE

Method for measuring transparent bottles using the ColorQuest XE, UltraScan PRO, and UltraScan VIS.

MM 5006 Measuring Coated Glass with ColorQuest XE

MM 5006 Measuring Coated Glass with ColorQuest XE

Measurement method for coated glass using the UltraScan PRO, ColorQuest XE, and UltraScan VIS.

MM 5013 Measuring Plastic Pellets with ColorQuest XE

MM 5013 Measuring Plastic Pellets with ColorQuest XE

Measurement method for plastic pellets using the ColorQuest XE, UltraScan PRO, or UltraScan VIS.

MM 5015 Measuring Dense or Opaque Bottle Preforms with ColorQuest XE

MM 5015 Measuring Dense or Opaque Bottle Preforms with ColorQuest XE

Measurement method for opaque or dense bottle preforms using the UltraScan VIS, ColorQuest XE, or UltraScan PRO.

MM 5016 Measuring Transparent Bottle Preforms with ColorQuest XE

MM 5016 Measuring Transparent Bottle Preforms with ColorQuest XE

Measurement method for metal surfaces using the UltraScan VIS, UltraScan PRO, or ColorQuest XE.

MM 5021 Measuring Translucent Solids with ColorQuest XE

MM 5021 Measuring Translucent Solids with ColorQuest XE

Measurement method for flat, translucent solids using the UltraScan PRO, UltraScan VIS, or ColorQuest XE.

MM 5022 Measuring Metal Surfaces with ColorQuest XE

MM 5022 Measuring Metal Surfaces with ColorQuest XE

Measurement method for metal surfaces using the UltraScan VIS, UltraScan PRO, or ColorQuest XE.

MM 5026 Measuring Translucent and Opaque Bottles with UltraScan VIS

MM 5026 Measuring Translucent and Opaque Bottles with UltraScan VIS

Measurement method for translucent and opaque bottles using the UltraScan VIS, UltraScan PRO, and ColorQuest XE.

MM 5027 Measuring Transparent Bottles with UltraScan VIS

MM 5027 Measuring Transparent Bottles with UltraScan VIS

Method for measuring transparent bottles using the ColorQuest XE, UltraScan PRO, and UltraScan VIS.

MM 5031 Measuring Coated Glass with UltraScan VIS

MM 5031 Measuring Coated Glass with UltraScan VIS

Measurement method for coated glass using the UltraScan PRO, ColorQuest XE, and UltraScan VIS.

MM 5038 Measuring Plastics Pellets with UltraScan VIS

MM 5038 Measuring Plastics Pellets with UltraScan VIS

Measurement method for plastic pellets using the ColorQuest XE, UltraScan PRO, or UltraScan VIS.

MM 5040 Measuring Opaque or Dense Bottle Preforms with UltraScan VIS

MM 5040 Measuring Opaque or Dense Bottle Preforms with UltraScan VIS

Measurement method for plastic pellets using the ColorQuest XE, UltraScan PRO, or UltraScan VIS.

MM 5041 Measuring Transparent Bottle Preforms with UltraScan VIS

MM 5041 Measuring Transparent Bottle Preforms with UltraScan VIS

Measurement method for metal surfaces using the UltraScan VIS, UltraScan PRO, or ColorQuest XE.

MM 5044 Measuring Flat Opaque Solids with UltraScan VIS

MM 5044 Measuring Flat Opaque Solids with UltraScan VIS

Measurement method for flat, opaque solids using the UltraScan PRO, UltraScan VIS, or ColorQuest XE.

MM 5046 Measuring Flat Translucent Solids with UltraScan VIS

MM 5046 Measuring Flat Translucent Solids with UltraScan VIS

Measurement method for flat, translucent solids using the UltraScan PRO, UltraScan VIS, or ColorQuest XE.

MM 5047 Measuring Metal Surfaces with UltraScan VIS

MM 5047 Measuring Metal Surfaces with UltraScan VIS

Measurement method for metal surfaces using the UltraScan VIS, UltraScan PRO, or ColorQuest XE.

MM 5051 Measuring Translucent and Opaque Bottles with UltraScan PRO

MM 5051 Measuring Translucent and Opaque Bottles with UltraScan PRO

Measurement method for translucent and opaque bottles using the UltraScan VIS, UltraScan PRO, and ColorQuest XE.

MM 5052 Measuring Transparent Bottles with UltraScan PRO

MM 5052 Measuring Transparent Bottles with UltraScan PRO

Measurement method for opaque or dense bottle preforms using the UltraScan VIS, ColorQuest XE, or UltraScan PRO.

MM 5056 Measuring Coated Glass with UltraScan PRO

MM 5056 Measuring Coated Glass with UltraScan PRO

Measurement method for coated glass using the UltraScan PRO, ColorQuest XE, and UltraScan VIS.

MM 5063 Measuring Plastics Pellets with UltraScan PRO

MM 5063 Measuring Plastics Pellets with UltraScan PRO

Measurement method for plastic pellets using the ColorQuest XE, UltraScan PRO, or UltraScan VIS.

MM 5065 Measuring Opaque or Dense Bottle Preforms with UltraScan PRO

MM 5065 Measuring Opaque or Dense Bottle Preforms with UltraScan PRO

Measurement method for transparent bottle preforms using the UltraScan VIS, ColorQuest XE, or UltraScan PRO.

MM 5066 Measuring Transparent Bottle Preforms with UltraScan PRO

MM 5066 Measuring Transparent Bottle Preforms with UltraScan PRO

Measurement method for metal surfaces using the UltraScan VIS, UltraScan PRO, or ColorQuest XE.

MM 5069 Measuring Flat Opaque Solids with UltraScan PRO

MM 5069 Measuring Flat Opaque Solids with UltraScan PRO

Measurement method for flat, opaque solids using the UltraScan PRO, UltraScan VIS, or ColorQuest XE.

MM 5071 Measuring Flat Translucent Solids with UltraScan PRO

MM 5071 Measuring Flat Translucent Solids with UltraScan PRO

Measurement method for flat, translucent solids using the UltraScan PRO, UltraScan VIS, or ColorQuest XE.

MM 5072 Measuring Metal Surfaces with UltraScan PRO

MM 5072 Measuring Metal Surfaces with UltraScan PRO

Measurement method for metal surfaces using the UltraScan VIS, UltraScan PRO, or ColorQuest XE.

Plastic Industry Brochure

Plastic Industry Brochure

Color measurement solutions for the plastics industry.

SpectraTrend HT for Plastics Brochure

SpectraTrend HT for Plastics Brochure

In-process plastic solutions using SpectraTrend HT.